DRY ICE CRYOGENIC CLEANING PROCESS

Cryogenic cleaning is an innovative technology aimed at removing unwanted coatings from various surfaces.

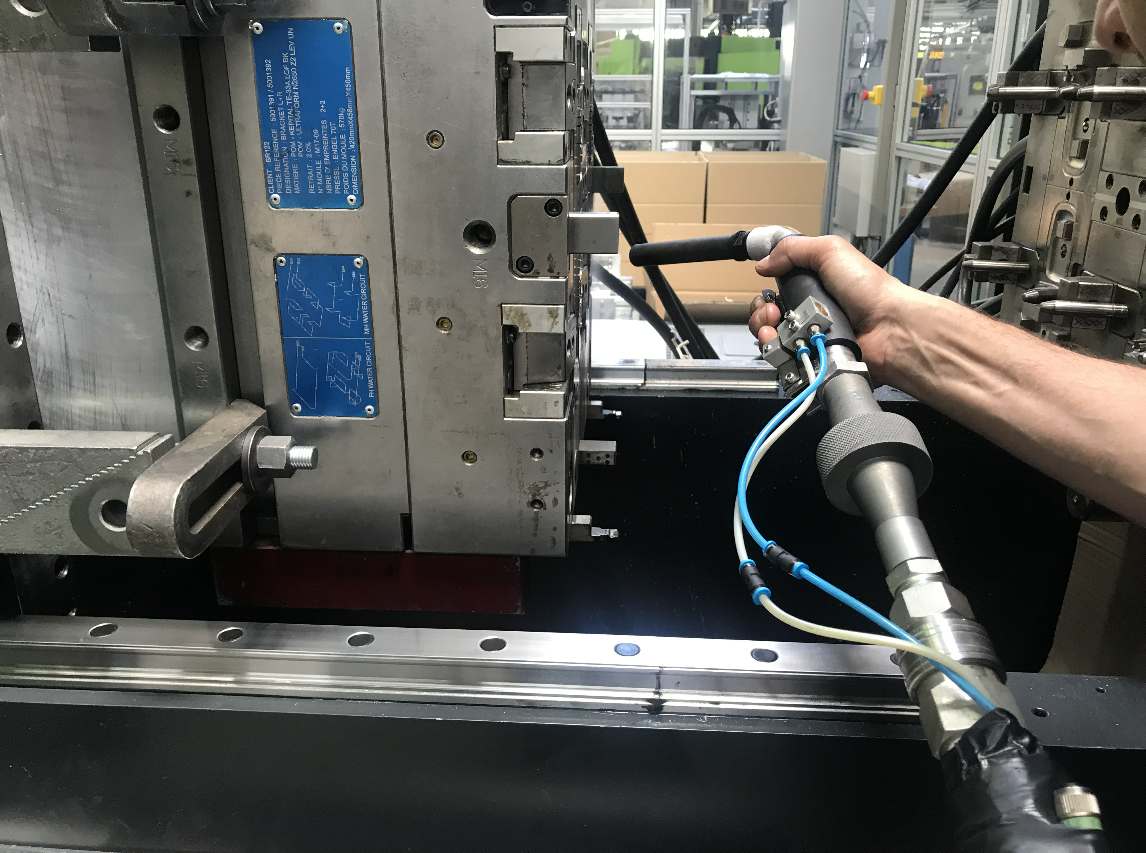

From machines developed specifically for dry ice blasting, the solid dry ice or dry ice is expelled thanks to the compressed air supplying the blasting machine to achieve the surface to be cleaned.

Dry ice cleaning

How does it work?

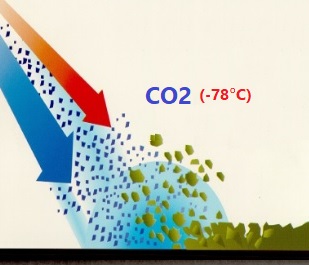

The principle of Cryogenic cleaning consists in sending a jet of dry ice (CO2) – 78°C on the surface to be cleaned.

This process is environmentally friendly due to its use of non-toxic and non-abrasive dry ice.This method sublimates the surface without damaging it and without leaving secondary waste.

The temperature of dry ice (-78°C) causes a thermal shock which destroys the adhesion of impurities to the treated support, without damaging the latter.

On contact with the surface, the CO2 instantly changes from the solid state to the gaseous state, thus multiplying its volume by 500. This phenomenon can be compared to chain micro-explosions, causing the complete detachment of the impurities.

Why opt for Cryogenic cleaning?

This ecological technique of cryogenic cleaning by dry ice blasting has many advantages and provides an incomparable result. Indeed, our process does not produce any additional waste and does not use water.

Dry ice at -78°C is pure CO2 ice and has the particularity of sublimate in contact with the support. At such temperatures, the fat molecules are “broken” and thus lose their hydrophobic characteristics: the cleaned surfaces are perfectly degreased, and this without the slightest use of solvent or degreaser.

This technique does not require any prior preparation, the security perimeter is very restricted and does not hinder the passage and activity of people on the site.

Similarly, it is not necessary to protect the parts electric, hydraulic or pneumatic, because this technology is not abrasive and non-conductive.

Dry ice cleaning: a non-conductive process

Dry ice blasting is a non-conductive process. It can be used for cleaning electrical and hydraulic equipment in service, and therefore under voltage: this helps to eliminate or reduce production stoppages.

Its non-conductive nature makes it an excellent choice for cleaning a variety of components, without the risk of electrocution: electrical cabinets, electronic boards, manufacturing processes for semiconductor wafers (for decontamination).

Dry ice blasting is a safe, efficient and environmentally friendly process for cleaning all industrial equipment.</ p>Dry ice at a very low temperature and leaves no residue. This makes it a very safe technique for cleaning sensitive medical devices, electronics and other equipment.

A non-abrasive and ecological technique

Cryogenic cleaning is a non-abrasive process. This is due to the nature of dry ice whose hardness is comparable to the hardness of chalk. The problem of pollution on semiconductor wafers is therefore perfectly eliminated, unlike the use of other processes to low pressure: dry ice is carbon dioxide recycled from other industrial processes. This method is more ecological because it does not produce secondary waste. In addition, dry ice does not damage the surrounding areas due to its sublimation: instantaneous transition from solid to gaseous state. Another advantage of this process is that it is faster than manual cleaning methods, 2 to 8 times. Furthermore, given its non-abrasive nature, cryogenic cleaning does not damage or degrade expensive molds, delicate components or semiconductor wafers. It is a very effective method for cleaning in place, without dismantling equipment where no additional steps are necessary.

Ask about our dry ice cleaning services! If you have any questions about the application process, don’t hesitate to contact us!